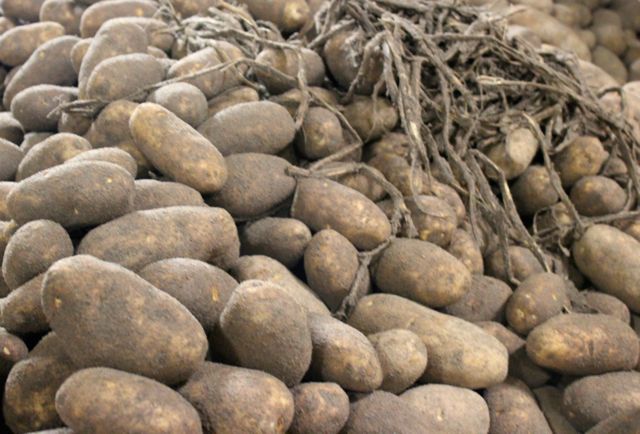

Have you ever seen so many potatoes? Imagine 13 billion pounds of potatoes…that’s how many are harvested each year in Idaho on 300,000 acres. 94 per cent of those potatoes are russets like these…and there are different varieties of russets too: Burbank, Norkotah, Ranger, and Western, to name a few. Idaho potato farmers also grow gold, pink, red, and fingerling potatoes. Only about 29% of those potatoes are for eating fresh, and 9% are for seeds. More than 60 per cent of all the potatoes grown are processed: frozen (french fries, hash browns, tater tots. etc.) or dehydrated as potato flakes and slices for instant mashed potatoes and casseroles.

Last week I was lucky enough to visit Idaho to celebrate the harvest with Idaho Potato Commission. I joined a small group of food bloggers and registered dietitians on tours of farms and potato processing facilities. On our first full day in Idaho we all piled into a bus and drove through the beautiful Idaho countryside. Acres and acres of potato fields had been readied for the harvest…plants cut and removed…potatoes in the ground, waiting for the harvest. Rainy weather was delaying the farmers, who needed the soil to be dry and dusty in order to get the machinery into the fields.

Our first stop was in American Falls at the Lamb Weston processing plant, the first one built in the 60’s by Lamb Weston to make frozen potato products, specifically french fries! We removed all our jewelry, donned hair nets and hard hats, signed into the visitors log book, and were ushered through the labyrinth of hallways to a conference room. There we saw a movie about Lamb Weston with an introduction to what we would see in the plant. It’s a good thing we saw that movie too, because it was so noisy inside the plant we could hardly hear our guides’ narrations. We learned how the potatoes are cleaned and how the skins are removed. We saw the special knives that cut the potatoes into fries, and innovation developed by Lamb Weston years ago that has come an industry standard.

We split up into small groups, climbing metal stairs, walking the cat walks, and observing all the intricate machinery that produces the cut and fried potato products we all love to eat. Later we were treated to samples of the foods they make, including McDonald’s french fries, sweet potato puffs, and jalapeño poppers. Each of the products they make are done to exacting standards dictated by their customers. Quality control and food safety are huge priorities in the plant. I was impressed that the people we met who work there have been doing their jobs for decades, taking enormous pride in their jobs and the company as a whole. Later I looked up Lamb Weston, and learned that they deserve to be proud of a legacy that includes some of the greatest innovations made over the last 60 years in the frozen produce industry.

Our next stop was Wada Farms, a 4th generation family operation that began in 1943 when Frank and Agnes Wada moved to Idaho to avoid internment during World War II, having moved from Japan to farm in San Clemente, Ca. in 1922. They started with 160 rented acres, increasing to 400 acres by 1972 when Frank retired, to over 30,000 acres in production today. The company motto is “Pride in Excellence”, and it is evident that the family’s adherence to that philosophy has contributed to their success.

All those potatoes moving through the machinery reminded me of a huge Mousetrap Game…or a choreographed dance!

Are you enjoying the trip so far? It’s fun to remember all that we saw and especially the warm welcome we received each place that we visited. We were disappointed that the weather wasn’t cooperating for the farmers’ harvest, and didn’t expect to be able to see any potatoes being harvested at all. Our hosts from the Idaho Potato Commission made some phone calls and found a farmer who was willing to let us visit his fields later in the afternoon. As we drove back toward Idaho Falls, we took in the huge open farm fields and the beautiful cloud formations in that enormous sky. It had been a long day, but we were giddy with anticipation! We were going to dig up potatoes ourselves on an Idaho potato farm!

To be continued…..

Disclaimer: I was invited on an expense-paid trip by the Idaho Potato Commission to celebrate the Idaho potato harvest. I was under no obligation to write this post, was not paid to write this post, and all opinions and experiences are mine.

4 Comments

Leave a reply →